Courtesy Peter Osborne

Fort Decker, our Society's historic stone house museum had been in need of a roof for many years. It was installed in 1974 and had long outlasted its useful life. Until 2007 we have been unable to secure funding to cover the cost of replacing it and making additional necessary repairs. After a major fund raising effort, the Society was able to piece together several grants that have allowed for the work to be undertaken. We will be installing a historically accurate cedar shingle roof, new copper flashing, repointing the chimneys, and installing new gutters. This is the biggest project completed at the Fort Decker Museum of History since we purchased the building in 1970.

The project was made possible by a matching grant from the Society of Colonial Wars in The State of New Jersey, the State of New York, donations by members and friends of the Society, Fellenzer Engineering, Luhr's Tru-Value Hardware and the Upper Delaware Scenic Byway. New York Senator John Bonacic was critical in obtaining the state grant to undertake project. We are grateful to all who have been involved with this project and who have assisted us with donations and grants. The project has been overseen by Peter Osborne, the Society's director, William Clark, a Society board member, Amador Laput, Project Engineer for Fellenzer Engineering, and Ken Sandri, the Assistant Director for Preservation and Resource Management at the Grey Towers National Historic Landmark.

To keep donors, members and the general public current with the project's progress we include a running diary here:

photo Courtesy Peter Osborne

April 25, 2009

Weather -Hot

Today we finish the masonry work that is being paid for by a New York state grant that Senator John Bonacic was able to obtain for us. John and Jose have done a beautiful job matching the original bedding mortar and cleaning off all of the old layers of mortar that have hidden the beauty of the original stonework from view for so many decades. In addition we have now sealed off the chimneys which were leaking and beginning to become a problem on the inside of the building. Because of the work, a large wet area which appeared in inclement weather on the western gabled end of the building is now fixed. I had long been worried that water would get in behind that area and freeze, pushing the stone out.

We will begin anew with the final monies that we have in hand in about two weeks when we repoint the entire front of the building. With that, until we have about $27,000 (or about $9,000 a side), we will have to try and raise additional funds for the project. If you would like to make a contribution to the cause please feel free to do so, contributions are tax-deductible to the extent allowed by law. We once again thank the taxpayers of our fair state and the efforts of Senator Bonacic for getting us this far.

We will proceed on.

April 22, 23, 24, 2009

Weather -Clear and cool

Work has proceeded on and now three of the walls are done. This contract has to been to restore the stone walls one foot down from the roof line. As this phase of the work is completed and now curing it becomes clearer how beautiful the stonework was when the building was first constructed. Each piece was carefully fitted and while some of the stone has been loosened as mortar is cleared out much of it is still tight. Behind the various layers of cement is the original bedding mortar all the way from the basement to the top of the building. Close up photographs demonstrate how much stone, large and small was needed and how difficult it was to fit each piece into place as the mason was thinking about various factors including shape, finish and the look of the whole structure.

While there was a significant amount of spot pointing around the building, there appears to be four different mortar mixes that can be found throughout the building. The first is the bedding mortar upon which the current mortar mix is based and what was used in the original construction. In the peak of the western side of the building bedding mortar was found that retained its original consistency and was not reduced to a powder form. To date it appears that entire building was built using this mix. It can be found throughout, from the basement to the peaks and in the walls.

The second major repointing utilized a white lime and replaced or covered over the bedding mortar and in places is configured in a v-shape. The v-shape is not carried throughout the building. A brown Rosendale cement was then extensively used, particularly on the backside of the building. The final extensive repointing was done using a grainy sand mixture in the 1940s and 1950s. Each successive repointing covered old joints but the material was dashed out farther and farther onto the stone until the texture and shapes of the stonework has been hidden from view.

All of this is conjecture of course because there are so many pieces to this puzzle but as the work has unfolded we have discovered more things about the building's history. While all of the details may not be important now, by having saved samples and documented the work through photographs, future historians will be able to analyze the materials and come to their own conclusions.

On Monday we will finish with this portion of the contract.

We proceeded on.

All photos Courtesy Peter Osborne

April 21, 2009

Weather - Rainy, cold, late in the day clear

The second chimney is finished today and work begins on the northeast wall of the building. All the old materials are raked out and according to John the entire building must have been repointed at the time that the chimneys were done. The mortar mix is the same. There has been much spot pointing over the years, both previous to this major effort and subsequently as well. Frequent repairs have been done in certain places to replace missing or deteriorating mortar. When we are finished the appearance of the building will probably look as it did in 1793 in terms of the style and approximate color of mortar. From 1793 forward the spot pointing increasingly changed the appearance of the building so that the beauty of the stone work was lost by small degrees every time repairs were made.

As I watch the wall being raked out more of the bed mortar, the original mortar used on the building is found deep in the joints, crumbling and having the appearance of powder. There are also slight variations on the main color. John has a very specification that he must meet but the original builders were not worried about maintaining a consistent look, they were trying to get the job done.

We keep more samples. As more and more of the original stonework becomes visible the skills of the original stone mason becomes more evident. The stone is all tightly fit together with at least one side of the stone being faced and in some cases, five sides having been shaped.

As I watch I am again reminded of the builders and the huge effort it would have taken to build the building. First the basement had to be dug out, stone found to build the structure and then the creation of the lime to be used with the sand as mortar. And then the interior structure and roof had to be built. It is a process that could have easily taken several months John thinks. Today houses are stick built and can be made at our local home builder's factory in a matter of days not months. As I watch John and Jose Colon working I am taken back to the eighteenth century and remember that the tools were pretty similar, the scaffolding would have been built of wood. Some kind of crane would have been built to lift stone into place. The raw strength to lift and move and shove has not changed.

Since the walls are eighteen inches thick in places one can see how much stone would have been required to build it. And then each piece has to be cut, lifted and put into place. This was not a job for the weak or timid. What is most remarkable to me after all these years is how square the building still is. When one looks at the corners there is no bow or shift in the alignment. That is a real tribute to the builders.

There was at one time a large number of stone houses in our region but today there are less than fifteen left and that is probably generous. The houses fell into disrepair as new styles of buildings became popular including the use of timber frames and then balloon frames which were easier to build. In some cases new frame additions were put onto stone structures. In the city of Port Jervis I believe that this is the last eighteenth century stone house still in existence.

I have reflected earlier how I have been the caretaker of this building for almost thirty years, longer than anyone else except the Deckers. I will not live to see this mortar repaired or replaced again. I want to be sure it is done right, not only from a technical point of view but from a restoration point of view.

All photos Courtesy Peter Osborne

April 17, 2009

Weather - Beautiful and clear

Once again we are underway with restoration work on the old fort. The grant being used for this phase was obtained by New York State Senator John Bonacic, a great friend of our Society and donations made by our members. This grant has taken us almost one year to process and use but as I watch the work being done I know that I will not see this work have to be done again in my lifetime. We are grateful to our Senator and the taxpayers of our great state.

The repointing begins and the color that we have chosen looks great and it is heartening to know that all the research has paid off. The new work looks as it did in an earlier time, recessed into the joint slightly creating a shadow effect. Later repointing efforts dashed cement over the original materials creating a smaller and smaller amount of stone to be seen. The new look will be much more accurate and showcase the stone. It also reminds us that earlier residents had to be miserly with lime because it was complicated and time consuming process to make lime putty with sand.

Once the chimneys have been raked out it is determined that the western chimney had been taken down and entirely relaid in the 1950s or 1960s. I am really surprised by this finding and once I get up the scaffolding and see for myself I realize I have never heard or seen anything about this. This was about the time when the last family, the Campfield lived in the building and then left it in 1958.

This revelation was evidenced by a brick lining inside of the chimney that was used to firm up the structure and was from the era, and finally, the fact that some of the stone had been cut with a circular saw. Further investigation of photographs revealed that the chimney is not as tall as it was originally. It appears that much of the stone was reused although not put back into its original alignment. It is thought that the chimney was rebuilt from the roof line up. The caps were placed on top of the chimneys in the 1970s after the Society purchased the building. The mortar on the chimneys has been slicked over twice since their reconstruction.

As I think back on it I have long puzzled about why some of the stone work was not level near the roof line. All of the stone work above it is laid out very nicely. But at the base of the western chimney the stone work is not level, it almost appears as if the chimney may have collapsed or settled at one point. Or perhaps it reflects the stone work of the 1950-1960s era masons. It seems so unlikely that those early stone masons would have done such a slipshod job in the 1790s although it is not impossible.

This process also demonstrates how historians have to use many lines of evidence to research a building, an event or a person. Someday I will bet that we will find a newspaper article that describes what happened to the chimneys. It would have been a major project to remove all the stone, bring it down to ground level and then move it back up into place. Other repairs or renovations to the building have been previously documented in the local newspaper. Unfortunately it would consume huge amounts of time to research a twenty year span of newspapers to find what might just be several sentences.

In this case there is no paper trail yet but there is material evidence that supports this conclusion. It also confirms what I have long thought about the building and that is there is no one date that we can restore it to because so many changes have been made over the years. If we were to restore it say to 1760, when it was built, we would need to take the top floor off. We would have to use a lime/sand mortar that would need to be replaced regularly. If we restored it to 1793, the year on the date stone, we would have to strip much of the early 19th century woodwork out and take the porch off. If we were to restore it to the 1820s, we would need to build an addition out of the back of the building. As the reader will see this creates all kinds of problems. The best we can do is document what we are doing, save the data for future interpretation.

We proceeded on.

All photos Courtesy Peter Osborne

April 16, 2009

Weather - Beautiful and clear

Today we commence the next phase of our roof project as we begin repointing the chimneys and a one foot band around the roof line to seal up breaks in the mortar at the place where the roof structure meets the stone walls. John Anderson was here setting up the scaffolding, unloaded materials and discussing the project with me. Tomorrow we will begin in earnest.

April 14, 2009

Weather - Cloudy and cool

We are back underway with what we are now calling "Fort Decker Museum of History Roof and Masonry Restoration Project" as we begin to expand the focus of our project. We have been working towards picking the final masonry sample that we will be using and while to everyone else it is just a simple decision I have been more mindful of the history of the building. I have never done anything that was not reversible during my thirty years as the building's caretaker. During my time much has been done and documented but could be undone if it needed to be. This is one of the tenets of historic preservation.

In picking the masonry the basic recipe is a given, three or four parts sand, one part white Portland cement and one half part lime. In using this mix the cement will be lighter and able to be colored through the use of sand. If you use a Portland gray cement, aside from lightening the color a little there is little ability to change the grayish cast. In analyzing the mortar on the building it is clear now that it has been repointed and repaired many times since 1793. To document each time would probably be a hopeless task. One of my goals in the next phase of this project is to document the various styles of mortar and colors that have been used. The range is quite interesting and difficult to piece together.

My larger concern is to get the color right because the basic mix has been approved by the State historic preservation office and Ken Sandri, our consultant who has worked on many similar projects. A softer mix, which would be more historically accurate, could be made but it is not as strong and will not last as long. It is thought that the mix we are going to use could last seventy years. In looking for original color we believe that we have found the earliest mortar which then gives us a sample to work from. There are several places where it can still be found in back of newer mortar on the exterior of the building and in the basement.

Yesterday I called my old pal Bill Clark because I was still concerned that I get this right. He suggested that we dig around in the basement and find a sample of the original mortar. With that we did. It is a sandy, soft mixture that just crumbles in your hand. I then called John Anderson, our mason contractor and he confirmed what I had thought. He believed that the original mix was made of sand (probably from the basement of the building) and lime (taken from baked limestone) and that it had simply deteriorated over time to its current condition.

We put some muriatic acid on the samples that John had prepared for us which eliminates some of the wash effect and got to the true color. In addition, John told me that mortar gets darker with age and since that is the case, the mortar we use will darken to the original color that we have found. In the end, a long process but a useful one. As John said, you can never match a color perfectly because is always changing.

On another front we are addressing some other maintenance issues that have long needed our attention. We are taking down two trees today on the property. We now introduce two new partners in this effort, Nelson Tree Service, Orange and Rockland Utilities and of course the City of Port Jervis. One of the trees is next to the Fort and other next to the Kleinstuber House. Both have become huge trees but also a major nuisance. The tulip tree in front of Fort Decker was planted in the 1980s to honor Dr. Daniel Schultz, a board member and area physician. The tree was located there because a former board member (not a family member to be sure) insisted that it go there. At the time I thought it was a bad location but I conceded the point.

As the years have gone by it has gotten larger and has begun to damage our sidewalk and handicapped ramp. Now that our new roof is on the building I am also concerned that the tree could damage the roof, either by having branches fall or shading it. From an aesthetic point of view it also covered part of the front of the building. Now a potential major nuisance will be eliminated. We will plant a new tree in Doc Schultz's honor on the property. Doc was a lovely man and a beloved doctor. I remember him once describing a cranky woman by saying that he had found that "She always did have a raspy disposition." More about that tree in future posts.

We are grateful for the efforts on our behalf of Barry Short our community representative at Orange and Rockland Utilities for his help in this major effort. He made all of the arrangements that allowed this project to happen and has long been a friend to our Society. We are also grateful again to the city of Port Jervis who had to help with disposal of the trees.

I am also pleased to report that the National Trust For Historic Preservation has noticed my blog here about our roof project. Roberta Lane, the program officer and regional attorney for the Northeast Office visited last week and told me how the trust was considering using our blog as an example of how history is preserved in this digital age in their national magazine. Thank you Roberta for stopping by, it was great talking to you.

All photos Courtesy Peter Osborne

March 20, 21 and 23, 2009

Weather - Clear and cool

We have begun the next phase of our roof restoration project. The phase calls for the installation of a new porch deck and porch posts by Duraframe. The porch has been a source of some discussion over the years as members have debated whether to keep it or not. The original porch certainly dates from after 1825 and some have even suggested the 1860s which certainly makes it an addition long after the building was built. Aside from the porch roof structure, nothing remains of the original deck or frame.

We do have the original posts, they were replaced years ago when the bases rotted away. Since then we have replaced the posts twice and the decking has been replaced three times in the last thirty years. What may have been the original frame was dismantled when the first deck was put on in the early 1980s. It was very deteriorated. At the time there were also side rails that may have dated to the early part of the twentieth century.

In the 1980s porch replacement a large rat skeleton was found as well as his home next to the foundation. We also found a lot of cobble stones and stones that could have been used in the construction of the building. Aside from that there was really no other pieces of historic evidence. We have kept the deck frame made of pressure treated lumber, installed new fir decking and pressure treated posts that are identical to the originals. The left post was completely rotted, having been eaten by termites.

After three days of work Duraframe completes its mission and we have a new porch. Once again the men of Duraframe have done a good job and the debate about whether to replace the porch will have to be put off until another day.

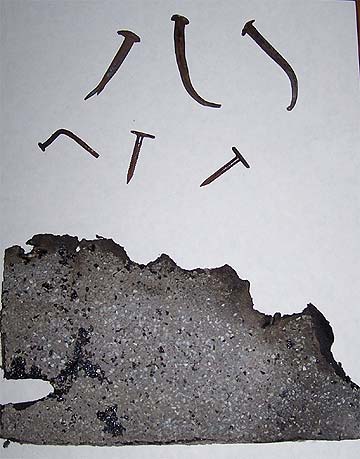

We have met with John Anderson of Cresco, Pennsylvania who will be our mason for the next phase of work. He will be pointing a band around the building two feet down from the roof line and the entire front of the building if funding allows. In addition, he has offered a significant donation of time and material to undertake work around the foundation line of the building. He has prepared samples which are pictured. Our roofing subcommittee has met and agreed that the lighter sample more accurately reflects the color of the earliest masonry used on the building. He will begin his work in mid-April when temperatures are warmer.

All photos Courtesy Peter Osborne

February 13, 2009

Today we will undertake what I have long thought was going to be the most difficult part of the project, hoisting the gutters up into place without twisting or bending them. There is a lot of money and effort riding on that short journey up the ladders and onto the spikes. First the resin is double coated on the inside of the gutter and then the exterior is repainted.

As we wait for the paint and resin to dry we have important business to conduct. Bill Clark has been worried that squirrels and bats will get into the space between the roof and fascia board. We have had squirrel problems in the past and so his concern is quite justified. So to address that issue we create a small "L" shaped piece of aluminum and put it into place. I pick up a piece and call it the Bill Clark Honorary Aluminum Trim To Keep The Bats and Squirrels Out. We all sign it and present it to him at lunch.

With that the final installation of the gutters begins. I am admittedly the project manager of the "Raise The Roof" campaign but a man with construction skills I am not. I can tell you what I want, I can get a contract together, I can raise the money and I can document a project and see it to fruition. I can design solutions and be a leader. However for a moment I join the boys and help pick up an end of the gutter although I am pretty worthless in this effort.

The back gutter goes up pretty easily and is attached to the blocking and then we move onto the front side. I have included a series of photographs to show how it was done. After the blocking is attached to the gutter the clean up begins some final finish work is completed and by the end of the day we all stand on the other side of the street admiring the building.

For me it is a dream of almost thirty years come true, for Duraframe there is a sense of pride in a job well done and for Amador, Ken, Bill and Rob there is probably a sense that finally they will have peace. They will not have to deal with me anymore and all the numerous phone consultations and challenges to fix. As I wrote earlier, I think that the Fort stands a little taller because of all this fine effort.

In the next two weeks Duraframe will be back to replace the porch decking and posts. After that John Anderson of Cresco will begin working on the masonry aspect of the project. Stay tuned as we keep you posted on our project's progress.

To all who have helped along the way we are grateful and certainly the old Decker Stone House is grateful. Martinus Decker's personal motto was Perseverance and Vigilance - we all have demonstrated those characteristics on this project.

All photos Courtesy Peter Osborne

February 12, 2009

Weather - Rain, cold - 40 degrees

Duraframe is back on site with our recreated metal spikes to hold up the gutter system. The spikes look great and look just as they might have in the eighteenth century. The installation of the gutter system requires some intricate calculations which include a drop from one end of the gutter to the other end which allows for water drainage and then the proper distance from the fascia board so that water drips off of the roof and into the gutter.

On Friday we had a round of discussions about whether to use "L" brackets as we had originally planned or to go to a more accurate look using spikes. The gutters would rest on the spike which would have a lip at the end to keep it from sliding off. There was concern that if the gutters filled with water and froze that the weight of everything might push the gutter away and tip it over. So we come up with the solution of placing blocking behind the gutter at each spike. The blocking will be screwed into the beam and gutter will be attached to the blocking. From the front it will not be visible. You will only be able to see this if you are directly underneath the gutter.

The spikes go in as planned and the blocking is created after having been measured before manufacture. So after a day of preparations, measurements and analysis we are ready for the installation of the gutters. The technique for hanging the gutters on a row of spikes would have been familiar to Martinus Decker although using resin to line the inside of them would have been a great improvement over what he used. Decker probably lined the inside with oil or perhaps just let them drain the water without treatment and replaced them when necessary.

In thinking about roofs past, I have figured out a rough scenario of how many roofs may have been on the building. Using thirty years as a rough parameter the following indicates how many roofs may have been on the building:

- 1793-1820- Cedar shingle roof

- 1820-1850 - Cedar shingle roof

- 1850-1880 - Cedar shingle roof

- 1880-1903 - Cedar shingle roof

- 1903- 1940 - Cedar shingle roof

- 1940-1974 - Grey-green asphalt roof

- 1974-2009 - Brown asphalt roof

- 2009 - Cedar shingle roof

We proceeded on . . .

Courtesy Peter Osborne

February 9, 2009

Weather - Clear, 40

Today the porch roof is finished as the flashing is completed, shingles and ridge boards installed. The ladders are removed and for the first time the beauty of the workmanship of Duraframe is evident. It has been a great experience to watch the work being done by such competent workmen. I have had the opportunity to hire other contractors over the years and some are a nightmare to deal with and others are pleasure to deal with. Duraframe is certainly of the latter category. As I have said previously, I will not be here to see the installation of a new roof on the Fort Decker Museum of History so I have wanted it to be done right.

The last part of the project will be to install the gutters. We are now waiting on spikes to be manufactured that will replicate how the original water drainage system was hung on the building. This brings our diary to a close for about a week to ten days as we wait for the supplier. The installation of the gutters should take about two days and then this phase of the project will be closed out.

We proceeded on . . .

Courtesy Peter Osborne

February 6, 2009

Weather - Clear, 40

Work on the gutters is now complete and they are moved by Duraframe from the DPW barn across town to the Fort Decker Museum of History. I watch with a little concern because if the gutters get twisted, dropped or improperly placed on the scaffolding on which they will be transported, a lot of work will go down the drain. However in the end the move is uneventful, and successful. The gutters are unloaded and placed on sawhorses at Fort Decker. I should not have doubted the ability of Duraframe!

The repair work on the porch roof is now underway and it is determined to replace all of the sheathing on the porch because the historic materials are simply crumbling or "baked" as Ken Sandri describes the process. The framework on which the sheathing sets is good but the sun has cooked the sheathing for more than one hundred years.

In analyzing the nails we find that they are cut nails and could date back to 1825. They are probably later because they have a stamped head on them and we have an 1825-1830 image of the building that does not show a porch on it. The sheathing was cut with an up and down saw and so could date as late as 1865 but as early as the late 1700s. We also have a 1902 line drawing of the building that shows the porch in place. In addition, there is an insurance map that does not show a porch on the building in the early years of the twentieth century. And to make this all the more confusing, I have long speculated that the porch was put on the mid-nineteenth century.

We proceeded on . . .

All photos Courtesy Peter Osborne

February 5, 2009

Weather - Clear, 40

Work continues on the gutters. The inside corners are lined with fiberglass cloth and then a resin is applied on the entire inside of the gutter. This process allows for the gutters to be sealed without the problems that can sometimes come with copper or rubber linings. We are using a design that has been used with success at Washington's Headquarters in Newburgh, New York. We are grateful to Jim Decker and the staff at Washington's Headquarters who helped us with this part of the project. They too have been great partners.

During the course of the day there are discussions about how the gutters are going to be hung. A spike design has been created by Ken Sandri and approved by Amador Laput. The spike will be very similar to what might have been used in the eighteenth century.

We proceeded on . . .

February 4, 2009

Weather - Clear, 40

Work on the gutters begins today and once they are constructed I realize how long a forty-foot gutter really is. To think about how to transport them and then lift them up onto the roof is something I am glad I do not have to worry about. Ryan will deal with that logistical nightmare. The backside of the building will be a relatively easy move once the ladders and hangers are in place. However the front side provides the additional challenge with the porch.

The gutters also have to hold a tremendous amount of weight. Consider the notion that if they are filled with ice and then had snow piled on top, that would be a lot of weight for the gutter hangers to hold. It could be hundreds and hundreds of pounds. Also, as the gutters are moved and lifted into place they cannot be twisted or turned because that will crack them. In the coming days we will be writing more about them but stay tuned because this is going to be one of the trickier parts of the project.

We proceeded on . . .

Vince Lopez, Port Jervis DPW

All photos Courtesy Peter Osborne

February 3, 2009

Weather - Cloudy, snowing 30

The focus is now on the front porch which has long created a dilemma for me. We have believed that the porch was added sometime during the mid-nineteenth century although we have no basis for that in the record. We know that in the late 1820s there was no porch on the building, just a small roof over the front door. There was a paneled front door typical of the period. This had replaced an earlier Dutch door that had two sections, the upper was kept open while the lower section was kept closed to keep the barn animals out of the house.

Years ago the Society's president, Charles Swartwout wanted to get rid of the porch and threatened me, in a humorous way, that someday I would wake up and walk in front of the Fort and find the porch gone. Our current president, Robert Schultz feels to some degree the same way. So far I have been able to keep the porch because it represents one chapter of the building's history. Fort Decker's architectural legacy does not represent just one period of time but rather two hundred years of changes, additions and deletions. This project has illustrated that very well.

Once the asphalt roof is pulled off the porch we find that the sheathing is badly damaged from the ravages of time. One of the surprises for me is how old the roof is, there are cut nails and sheathing boards that are very similar to the ones on the upper roof. Perhaps they are fragments of board from repairs that were made later. There are also some boards with up-and-down saw marks on them. As I look back over the pictures I have taken I wonder if we will have to revise our thinking about the date of the porch. The earliest image of the building that we have is a late 1820's sign board.

After this project is complete I will have to update my book that I wrote last year on Fort Decker. In studying older photographs that we have, and in looking at the samples that we have pulled, revisions will be in order. We now understand the building's history a little better than when we started. This was an important goal of mine when the project started.

We have a series of discussions on how to proceed with the porch roof and then agree as to how to deal with several other issues including the size of the gutters, the gutter hangers and how we are going to close the gap between the frieze board and roof overhang.

We proceeded on . . .

All photos Courtesy Peter Osborne

February 2, 2009

Weather - Cloudy, 40

Work on the flashing has been finished along with the installation of lead into the joints where the flashing meets the stone. When you read the label for the installation it is a pretty daunting warning. You must wear gloves, you must clean your hands regularly and not allow it to get into your system. It is of course deadly stuff. That said, it is also the material that gives the flashing a most handsome and finished look.

We also have a visit by Matt Osterberg today. Matt is a board member of the Society and not only gave a substantial personal donation to get this project started but he also got his employer, Luhr's TruValue Hardware in Milford, to donate the differential between the wholesale and retail costs of the shingles to the Society. Matt has long encouraged me on this project and was one of the early supporters of putting a wood shingle roof on the building instead of an asphalt roof. He is very pleased with the job so far and is glad to have been of assistance. I have long believed that it is people like Matt who have a sense of community spirit and pride that make projects like this happen. Over the years he has written a number of books and donated the royalties to our Society. I am proud to say that I have written the introductions to three of them. Thank you Matt.

The project is beginning to wind down as the scaffolding is taken down, the roof swept and work area is being cleaned up. By the end of the week we are pretty much going to be done. We have met with another of our new partners in this project, the Port Jervis Department of Public Works and Vince Lopez. Vince is the director of the city's largest agency. The DPW and the Society have partnered on many projects over the years. When I call Vince it is never just for pleasantries or taking him out for a cup of coffee (which I probably owe him a few of), it is always about a project that we are working on together. Last week when I called he knew I needed something. The DPW is going to allow us to use one of their bays to construct the gutters which will be approximately forty feet long and have to be moved in one piece because of their unique construction.

We proceeded on . . .

Matt Osterberg

All photos Courtesy Peter Osborne

January 31, 2009

Weather - Sunny, clear, 38

Today is simply a beautiful day to be atop the old stone house. I suppose that Duraframe's men have taken an occasional moment to look at the wide flat vista around them. Fort Decker was once part of a large farm, extending to the Delaware River, to the foothill of Mount William and Point Peter, to the boundary line with the present day fire department and then out across the flats towards the center of where the railroad operations were at one time. A related family, the Caskeys, owned an adjacent farm at a later date that continued to Sparrowbush. The location is strategic as well because its residents could see far off into the distance although that did not make any difference on the day that the building was burned down on July 19, 1779. Brant swept through with his Loyalists and fellow Native Americans and destroyed what was then known as the "Martinus Decker Settlement" with its "piquet" fence surrounding it.

From the roof one can see clearly High Point, over to beginnings of the Pocono Plateau in present-day Matamoras, and up the river valley. I have often sat on the porch in the spring wondering what that view must have been like when the Deckers lived here. It would have been a broad flat area with no houses except for the outbuildings of the farm. The acres of corn and wheat must have been a beautiful site to see. Martinus Decker would not live to see the day when Port Jervis would become a railroad center or know that his farm was a critical piece of property in the development of both the Delaware and Hudson Canal and Erie Railroad's facilities here.

Today work has focused again on the flashing and the installation of the ridge board along the peak of the roof. By the end of the day most of the flashing is done and the ridge board is installed.

One of our important partners in this project has been the Grey Towers National Historic Landmark in Milford, Pennsylvania. Our contact has been Ken Sandri who has done a fine job assisting with our specifications and project oversight. Without him our project could not have been accomplished. He has not been afraid to get up on the roof or wander around taking pictures. I have the same feeling about Amador Laput, our project engineer who has dealt with the paperwork, granting agencies and oversight. We are grateful to Fellenzer Engineering for loaning us Amador for the last few months. I am sure Fellenzer Engineering will be very happy when we return him.

My old pal and board member Bill Clark has been working on this project since its inception. He always urged caution but also encouraged me to get the job done right the first time. He read the specifications several times and has been here most days overseeing the work and covering for me on occasion when I could not be here at the beginning of the day. Finally I would be remiss if I did not mention the final member of our roof subcommittee, Robert Schultz, our Society's president. Its never a good thing not to mention your boss in the kudos! Unfortunately I do not have a picture of him on the job site, we will have to work on that. We are grateful for all their hard work, this has been one of the best committees I have ever sat on.

We proceeded on . . .

Courtesy Peter Osborne

January 29, 2009

Weather - Sunny, cold, 28

The work continues as Duraframe's men are now working on the copper flashing and counter flashing at the place where the chimney meets the roof. Tom believes that the small stone ledges that protrude from the chimney at the roof line were the original flashing. With the shingles tucked up underneath the ledge, water would have been prevented from coming in on that side of the chimney. On the side that is perpendicular to the ledge, the shingles would have been butted right up against the chimney and pine pitch might have been used to seal that joint. That would have been the only place where water might have come in and it would have come down inside and on the part of the chimney that faced into the room.

This part of a roofing project always requires great skill because if the fit is not tight the roof will leak. The previous flashing was made from aluminum and while it had held up for forty years, the joints were now beginning to leak. The copper is also a handsome addition to a roof that has given our building an entirely new character. I always like to say that historic buildings stand a little taller after they have been restored. I know my reader might think that a little whimsical but that is a long-held belief of mine.

It is also quite evident that masonry joints are in need of immediate attention. The masonry portion of this restoration project will begin in several months when both chimneys are entirely repointed. There are large gaps between stones and the pointing is very deteriorated. The masonry contract will be funded by a grant from the state of New York that was obtained for the Society by New York State Senator John Bonacic.

One of our important partners in this project has been the Grey Towers National Historic Landmark in Milford, Pennsylvania. Our contact has been Ken Sandri who has done a fine job assisting with our specifications and project oversight. Without him our project could not have been accomplished. He has not been afraid to get up on the roof or wander around taking pictures. I have the same feeling about Amador Laput, our project engineer who has dealt with the paperwork, granting agencies and oversight. We are grateful to Fellenzer Engineering for loaning us Amador for the last few months. I am sure Fellenzer Engineering will be very happy when we return him.

My old pal and board member Bill Clark has been working on this project since its inception. He always urged caution but also encouraged me to get the job done right the first time. He read the specifications several times and has been here most days overseeing the work and covering for me on occasion when I could not be here at the beginning of the day. Finally I would be remiss if I did not mention the final member of our roof subcommittee, Robert Schultz, our Society's president. Its never a good thing not to mention your boss in the kudos! Unfortunately I do not have a picture of him on the job site, we will have to work on that. We are grateful for all their hard work, this has been one of the best committees I have ever sat on.

We proceeded on . . .

Ken Sandri - Courtesy Peter Osborne

Amador Laput - Courtesy Peter Osborne

Bill Clark - Courtesy Peter Osborne

Courtesy Peter Osborne

Courtesy Peter Osborne

January 28, 2009

Weather - Snow and ice

Work has come to a halt with the heavy snow and ice falling. The roof was covered last night so there will be no problems on Thursday when we begin anew.

January 26, 2009

Weather - Sunny but partly cloudy, 35

Work proceeds on the front section of the roof. While I do not think it was balmy, work really moved along at a nice pace today. By the end of the day the main roof was essentially finished except for the gutters, flashing, ridge board, a handful of shingles and the front porch. As I watched the final row of shingles being installed on the ridge line I could not help but remember the many people, agencies and institutions who have gotten us here. As I mentioned earlier in my posts this has been a two-year long effort that has brought together a number of partners including the following: Society of Colonial Wars of the State Of New Jersey, New York State through Offices of Senator John Bonacic, the Upper Delaware Scenic Byway, Fellenzer Engineering, Grey Towers National Historic Landmark, Luhr's Tru-Value and the many donors who have given us money, all of whom are listed at the bottom of this page.

I want to mention in particular the Society of Colonial Wars because their grant, which required matching funds or in-kind services, enabled us to broaden our efforts to complete this project. The matching requirement saw us create partnerships with Luhr's, Grey Towers, Fellenzer Engineering, the State of New York and the City of Port Jervis. The Society has been involved with many collaborative partnerships before but this one is the most extensive ever undertaken. I believe that there are other projects on the horizon where we may all work together again.

On a personal note I cannot help but remember all the donors who gave money in memory of Janis. Since the apartment we lived in overlooks Fort Decker we have admired it close up for many years and it was very much a part of our lives. She once wrote about the old stone house,

"I love that building so. It's almost like a person to me. Have many fond memories of it - from the very first day I stepped inside."

In a biography I wrote about her last year entitled "For Always: Memory of Janis" I said:

She loved Fort Decker and volunteered to give tours there for many years when no other volunteers or members stepped forward. She was the only person who was allowed, if that is the right word, to smoke there. Janis and I designed the original herb garden and she helped to write the brochure. She also did a news story about it when we were done. She also made chive vinegar, using chives from the garden, with their purple flower heads flavoring the vinegar.

She refused to eat my eighteenth century cooking delights, probably with good reason. As someone once said to me - "If this was the 1770s and I had just come over the mountain and was tired and hungry, your hoe cake would taste pretty good. In 2006, it tastes terrible." But at the end of the day, because the Society could not afford to buy me an outfit, Janis said to go ahead but that I had better use it. Use it I did. She complained when my re-enactor's outfit came home smelling dreadfully, especially when I did not wash it for weeks at a time. After her passing people donated hundreds of dollars towards the roof restoration project that was going on at the time.

It is also worth remembering that two other people were memorialized with donations toward the roof fund - Tom Smith by Jerome Smith, our volunteer groundskeeper and Jerry Walters by Nancy and Charles Swartwout. Jerry and I worked on a number of projects over the years including the restoration of the Mahackamack Graveyard on East Main Street and the Pioneer Knoll Graveyard in Godeffroy. He was also the only person to have taken and kept several pictures of the interior of Fort Decker when the Society purchased it in 1970. I have to think he would be quite delighted with the current effort underway.

We proceeded on . . .

Courtesy Peter Osborne

January 26, 2009

Weather - Sunny, 21

It is cold again out on the roof of Fort Decker although the men of Duraframe don't think it is too bad. Work continues up the front section of the roof. We anticipate being done with this section later this week or early next. We will then move onto the flashing and gutters. For the gutters we will be duplicating a technique used at Washington's Headquarters in Newburgh, New York. At that historic site a variety of techniques were used to create leak-proof gutters including lining the wooden box gutters with copper, oil and rubber. All of those methods have failed to various degrees.

The site's maintenance staff have come up with another method creating problem-free gutters. This new process calls for covering the inside corners with fiberglass and then lining the entire inside of the gutter with resin sealing it from rain, snow and wet leaves. This is the process that we will use on this project.

Another tricky part of the gutters is their length. They will be about forty feet long and so will need to be made on site or nearby and carried over. We are trying to negotiate the use of the local fire department building that neighbors our property or the Department of Public Works barn. That is a challenge that we hope to settle in the next few days.

We proceeded on...

All photos Courtesy Peter Osborne

January 23, 2009

Weather - Sunny, 44

Another balmy day at Fort Decker as we have the warmest weather to date for the project and Duraframe's men. The new skip sheathing continues to be installed and the men make their way farther up the roof. The first layers of shingles are laid and we now consider ourselves at the halfway mark of the project.

While most cedar shingle roofs have a ridge line that have shingles turned sideways and nailed down, we are going to have a ridge board, a continuous board that will go across the entire length of the roof. Other roofs have the shingles extend above the ridge line, sticking out beyond the roof. However that style of finishing the roof off invariably leads to the shingles blowing off. We were given advice by one expert at Hudson Valley Dutch vernacular architecture to use a ridge board, something that he believes was much more common in times past. I have never seen a roof with a ridge line like that but I know it is going to have a handsome look to it. Beneath that will be an exposed piece of zinc that will release microscopic particles of zinc each time it rains so that algae does not grow on the roof.

I come back to the service of Martinus Decker as I watch the men work their way up to the ridge line. One of the things that continuously amazes me about Decker's service during the Revolutionary War is that he never took compensation for his war effort and his family never received any compensation, in the form of a pension, to which they were entitled for his brave war service. This was not uncommon for the local militia as attested to by David Van Inwagen in 1847:

On this tenth day of May 1847 personally appeared before the undersigned a Justice of the peace in and for the said County David Van Inwagen of the Town of Thompson in the County of Sullivan and State of New York but now in the town of Deerpark County of Orange and State aforesaid aged Eighty three years to me known as a man of truth and veracity who being first duly sworn according to law doth on his Oath depose and say that he was born and raised to manhood and lived until the last few years in the valley called Peenpack on the western frontiers of Orange and Ulster Counties - That during the Revolutionary war this valley was continually exposed to the depredations of the Indians who infested the mountains and woods west of the valley That the inhabitants were continually exposed to the scalping knife and tomahawk and several were killed at midday when at work in the fields . . . He is satisfied that from what he knew of the services of Lieut Martines Decker that he could not have done less than one year actual service as a Lieutenant during the war This deponent further saith that he never received any pay for any service that he done nor does he know of any of those who lived in the valley and served in the militia that did. He does not believe that Martines Decker received pay for services done on the western frontier of Orange and Ulster Counties - He was well acquainted with the said Decker until his death which took place in April 1802 This deponent was at the burial and saw his remains interred in the old Dutch burying ground near where now is built the village of Port Jervis.

Martinus Decker's stone is long gone but an early twentieth century marker was placed there by the Daughters of the Revolution. Recently we straightened it out and cleaned it.

Bill Clark, Brian Lewis and me are continuing to take pictures of the work's progress. Since Brian has a passion about history I have given him one of the old shingles, a new shingle and a hand-cut nail. He is from the next generation of history buffs that will need to preserve the building after I am gone. Perhaps those two pieces of eighteenth century history will inspire him to fight for the building's preservation. Hopefully he will stop a utility company from putting a meter on the front of the building or stripping out historic fabric in the building.

As to the nails, there is something about holding one of those nails in your hand. It was made by hand by a blacksmith, perhaps on site. The top is flattened to create the head and it has not seen the light of day since 1798. It has a "j" shape because as it was pulled out of a damaged board, it curled. There are also square nails with a large flat round head, perhaps from the early twentieth century. All of the samples will be stored at Fort Decker and surely be consulted by future historians. All tell a small part of the story of the Fort Decker Museum of History.

We proceeded on...

All photos Courtesy Peter Osborne

January 22, 2009

Weather - Cold, cloudy, 36

It is downright toasty up on the roof today as the efforts begin on the east side of the roof of Fort Decker. With back section done but for the flashing, work is now focusing on the front side and the scaffolding has now been moved to the front of the building. This new phase of the project is much more visible and has drawn a whole host of rubber neckers as they drive by and an occasional sidewalk superintendent. The condition of the front roof sheathing is not as good as the back. There are more damaged boards and at the center and near the top most of the sheathing has been replaced. Since new sheathing will be installed on top of the old this will not present any problems.

A board is removed and I am now able to see the roof superstructure and how it rests on the stonework. A huge beam rests on the top of the stone and upon that sits the rafters. For the first time since 1974 this area is now open to sunlight. Only a handful of people have ever seen this part of the building since it was constructed in 1793. There are elements of another asphalt shingle roof, perhaps a third one. We have found some old hand cut nails that speak to us from a distant time when each nail was made by hand. They almost look brand new. The interior walls are visible and it has been an occasional nesting place for squirrels.

With the new sheathing to be nailed into place, the front roof will go up much more quickly. It is supposed to be even warmer tomorrow. We are also looking towards other components of the project being completed including the installation of our gutters and a new porch deck and porch posts. All of this is part of the larger effort to stabilize the building well into the future.

We proceeded on.

All photos Courtesy Peter Osborne

January 19, 20, 21, 2009

Weather - Cold, cloudy, teens

Another interesting discovery is that the chimney has an interesting construction. At the juncture of the roof and chimney a small lip protrudes from each side of the chimney. It seems to indicate that the section of the chimney below the roof line may be of an earlier construction. The eastern chimney also has an odd configuration. Several of the stones are not level but decidedly tilted, something that is odd given that the rest of the building is so square as are the chimneys. It only reminds us that buildings often have histories of their own. A quirky feature created by the builder to fix a problem or challenge provides modern historians with questions to which there are no easy answers. This odd alignment of cut stones is one of them.

A final item is the type of wood that was used in the original sheathing. It is thought to be pine but we are not sure. There certainly was a lot of pine in the area at the time, in fact, acres and acres of forests.

As I continue to watch Duraframe's men work their way up the roof I am again drawn back to Martinus Decker, a second lieutenant in the Orange County militia during the American Revolution. The full transcription of his wartime service, remembered more than fifty years after he had fought the British and Indians, is attested to by his son who relayed the following:

On this sixth day of October 1840 personally appeared before the court of common please being a court of record in and for the County of Sussex and State of New Jersey John Decker a resident of the town of Wantage County of Sussex and State of New Jersey aged Seventy five years who being first duly sworn according to law doth on his oath make the following declaration in order to obtain the benefit of the provisions of the act of Congress passed July the 4th 1836 and the act explanatory of said act passed March the 3d 1837; That he is the son of Martinus Decker who was the husband of Mary Penneton who afterwards was the wife of John Middaugh and who was a widow on the 4 day of July 1836 and who died on the third day of April 1840.

He further declares that he is the only heir that he knows of living of Martinus Decker who was a Lieutenant in the militia of the County of Orange and State of New York That Martinus Decker was chosen by the company of militia under the command of Capt Moses Kortright and the Regiment commanded by Col William Allison in the winter of 1776 Benjamin Thurston was Lieut Colonel and John Decker Major That as he has been informed and believes his father Martinus Decker was called out under Capt Kortright to Fort Montgomery in the month of May or June 1776 and served one month this service was under Col Allison or Clinton. That he has been informed and believes that the said Martinus Decker after the battle of Long Island was again called out to Fort Montgomery and along the Hudson River and to Ramapoo and Paramus and was out one month in the said service as a Lieutenant under Capt Kortright and under Col Allison this was in August or September 1776. That in December of the said year Col Allisons Regiment was called out in a body to a place called New City in the county of Orange near the Hudson River Capt Kortrights company was out with the rest of the Regiment and Martinus Decker was out as a Lieutenant in the said company and served with the rest of the Regiment at New City and other places along the Hudson River from in December 1776 until about the twenty fourth of January 1777 and was discharged with the rest of the Regiment at the expiration of a service of Six weeks.

That in the spring of 1777 his father Martinus Decker was again called out to Tappan and other places along the frontiers of New Jersey under he believes Capt Jones and under Col Allison or Cooper and served fifteen days. That in August 1777 Col Allisons Regiment was called out to Fort Montgomery and Capt Kortrights company went with the rest of the Regiment and Martinus Decker went as the Lieutenant of the said company and after they had been there one month the Militia belonging to Col Allisons Regiment was discharged with orders to be ready at the first call in this service Martinus Decker served one month as a Lieutenant.

That immediately after Fort Montgomery was taken Col Allisons Regiment was called out under Col Thurston and Major John Decker to a place called Meurderes Creek on the Hudson River That the Company of Capt Kortright with Martinus as one of the Lieutenants went to Meurderes creek and Joined with the rest of the Regiment at that place and followed the British up the River as far as Bankses Bridge where a part of the men made a stand but he has understood and believes that Lieutenant Decker with a few choice men went as far as Kingston which before they reached it was burnt by the British who had retreated.

That the said Lieutenant Decker was present when the spy was hung who was taken when on his way to meet Gen Burgoyne. After He went to Kingston the company returned to New Windsor and after a service of one month Lieutenant Decker was discharged with the rest of the Regiment This service was done under Lieut Col Thurston and Major John Decker That in the Spring of 1778 the Indians began to make a formidable appearance on the western frontiers of Orange and Ulster Counties and threatened devastation to the whole frontier and the militia on the west side of the mountain was retained at home to guard along the said frontiers.

That the militia was Classed into detachments each detachment doing its duty in turn under the different officers of their respective companies Capt Kortrights company was one of those along the frontier and was retained to guard along the Delaware and Neversink Rivers but this declarant is unable to state with accuracy the different times that Lieutenant Decker was out in service except the following upon alarms and after Spies He has been informed and believes that in June 1778 the come down upon the frontiers in considerable force. Capt Kortrights company was called out to Martinus Deckers fort and served one week upon alarm and Lieutenant Decker served as a Lieutenant in the said Fort one week Col Newkirk or Pawling had command along the frontiers.

That in the month of October of the said year the Indians again made a decent (sic) upon the western frontiers of Orange and Ulster Counties and killed several of the inhabitants this made a general alarm and the militia of the surrounding country was called out Capt Kortrights company was called out to Dewitts fort and served two weeks under Col Pawling or Newkirk. In this service Lieutenant Decker was out two weeks as a Lieutenant.

That on the 19th (sic) of July 1779 the Indians made a decent (sic) upon Minisink and destroyed the property of the Inhabitants by fire the alarm was given and the militia was called out and followed the Indians to a place called Beaver brook Capt Kortrights company was called out and Lieutenant Decker was out in the said company as a Lieutenant from the time the alarm was given until he was discharged at least two weeks this service was under a part of the time under Col Hathorn and Tusten and the rest of the time was in the Fort called Deckers Fort.

That sometime in the summer of 1780 and while Col Seward of New Jersey had command along the Minisink frontier a report was circulated that there was Tories in the woods of Pennsylvania who assisted the Indians in committing their depredations upon the whites. Capt Kuykendolls of the New Jersey Militia was ordered out with a detachment of men a part of which was taken from Capt Kortrights Company and Martinus Decker went and served as a Lieutenant in the said company in fereting (sic) out the Tories at least one week.

In the spring of 1781 it was reported that spies was in the neighborhood of the Minisink frontier Lieutenant Decker was ordered out with a detachment of fifteen men to catch them they Rendezvoused at Levi Van Ettens and went to the Delaware crossed over to Pennsylvania and went through the woods to a place called Pond Eddy and recrossed to the York side of the River and went up the River to a place called ten mile River where they caught two of the spies named Robert Land and Edward Hicks in this service Martinus Decker served as a Lieutenant commandant for at least one week in June of the said year.

Capt Kortrights company was called out on alarm along the Delaware frontier and served three days in this alarm Lieutenant Decker served three days a Lieutenant That in August or September 1782 the Indians made a decent upon the western frontier of Ulster County and burnt Warwasink Capt Kortrights company was again called out and went to Dewitts fort and served two weeks and was discharged at the expiration of the said term Martinus Decker went with the said company and served in the said company as a Lieutenant for the term of two week under Col Pawling.

He further states that from the nature of the war along the frontier and from personal knowledge of a part of the same he has no doubt but his father Martinus Decker served at least two years as a Lieutenant in the Militia of Orange County He further declares that he served as the second Lieutenant of Capt Kortright and Capt Willhelemus Westfalls company during the whole of the war.

He further declares that his father Martinus Decker was married to Mary Penneton on the 27 day of August Seventeen hundred and Sixty Eight by the Rev Mr Marinus and that the said Martinus Decker died on the 24th day of April Eighteen hundred and two this deponent further saith that he is the son of Martinus Decker by a former wife that the widow of Martinus Decker was afterwards married on the fifth day of June - Eighteen Hundred and six - by the Rev W Van Benschocten in the town of Wantage and State of New Jersey and that to John Middaugh who died on the 22d day of February 1822 and that the said Mary Middaugh remained a widow until her death which happened at the time before stated That the said Mary Middaugh formerly Mary Decker Died without issue and that this This deponent is the son of Martinus Decker by his first wife and that he is the only heir of Martinus Decker that he knows living.

That the accompanying record of the family of Martinus Decker as sworn to by John Decker is a true record of the said family He hereby relinquishes every claim to a pension or annuity except the present and declares that the name of Martinus Decker or Mary Middaugh is not on the pension roll of the agency of any State in the Union Sworn and subscribed to the day and year aforesaid.

So as the men stand on the same wood that our Lt. Decker did, as the pound the nails home on the cedar shakes as he probably did, as they look out over the horizon as he surely must have, they follow in the footsteps of a dedicated patriot.

We are grateful to Barbara Bedell of the Times Herald Record who did a nice piece on our roof project in Sunday's newspaper. With that, we proceed on.

All photos Courtesy Peter Osborne

January 16, 2009

Weather - Sunny, cold, 5 degrees below zero

The work on the roof has halted as we have conceded to the harshness of the weather. Duraframe's men were on site but decided after a conference that even with the tent they had created yesterday it would be too cold to work. With that the day's efforts ended. Next week is supposed to be warmer.

January 15, 2009

Weather - Cloudy, snow, cold, 15 degrees

The roof project continues on in the bitter cold and to compound this challenging issue we had several inches of snow last night. Today Duraframe's ingenuity was demonstrated again as the men took the tarp that covers the unfinished roof and turned it into a thirty by forty-foot tent. With such an innovation they were able to work out of the severe cold. While it was good for them, it was bad for those of us who are documenting the project because we are unable to see what work is now going on. I can only tell the reader that the work continues on steadily.

Our roofing subcommittee meet today and it includes Ken Sandri, the Assistant Director for Preservation and Resource Management at Grey Towers Historic Landmark in Milford, Pennsylvania, Amador Laput, a project engineer from Fellenzer Engineering in Middletown, New York and William Clark, a Society board member. We all agreed that the work was excellent and the workmanship outstanding.

Today my journal entry is about me standing on my soap box about protecting the building's history. I have long loved and cherished this building that we are now putting a new roof on. I have walked around it thousands of times during my almost thirty years as the Society's director. I have worried about, I have painted it, I have cut its grass, cleaned its bathroom and I have been proud to give tours of it. I feel that part of my mission here is to hand it off to the next generation in better shape than I found it. But first a digression.

In 2008 I took a three month sabbatical and followed the trail of Captains Meriwether Lewis and William Clark from Washington, DC to the Pacific Ocean. I drove alone for more than 11,000 miles and visited many historic sites along the way. The Society's volunteers took over my duties during the time I was gone including Bill Clark. During my trip I wrote a book called Lewis and Clark and Me: A Voyage of Discovery and the following excerpt comes from my journal entry in the book dated August 27, 2008 when I was in Idaho. It reflects upon my own passion about the Fort Decker Museum of History:

"My day ends with a final phone call to Bill Clark. As it turns out, there has been a gas leak discovered in front of Fort Decker and it has been repaired. O & R had originally proposed putting a meter in the front of the building if a new one was needed. (Our present meter is out of view in the basement.) Oh be still my heart! Why the crew at O & R did not see what an insult that would be to our history I cannot say. But my friend Bill did. The leak is repaired and there is no need for a new meter. I knew there had to be at least one significant crisis at the Society while I was gone. "I am also reminded that I have long watched out for the building. "Long ago the city wanted to replace our bluestone sidewalks with cement walkways. I fought that one, the bluestone sidewalks remain. Last year the tree cutting guys wanted to take the top out of one of trees near the building. I stopped them. There was a need to make our building accessible for the handicapped and we were told we needed a wood ramp with a handrail that would have to go in front of the building. I got a designer (another kind and gentle man, Tom Burrows, who donated his time and professional experience), and along with Bill Clark, came up with an ADA-approved design that did not need a handrail if the pathway was long enough. With just a slight turn in the blacktop we accomplished the goal of making the building accessible to wheelchairs and preserving its handsome appearance.

"I believe that at least while I am in Port Jervis (or even in Lewiston, Idaho), it will be my mission to protect that building for generations to come. The builder, Martinus Decker, had a motto and it was "Perseverance and Vigilance." That is my own motto when it comes to defending the building I cherish from those who would put gas meters on the front of it. I will fight them to the end of my time there."

I will challenge those who want to put asphalt roofs on historic buildings to do better, to dream a little higher. And now as each day goes by I know that I will not live to see the installment of the next roof on this building. This is not something I will have worry about again in my time here with the Society. So endeth my soap box.

Bill Clark and I are continuing to take pictures of the work's progress.

We Proceeded On

All photos Courtesy Peter Osborne

January 14, 2009

Weather - sunny, cold, 20 degrees

The roof project continues on in the bitter cold as the men of Duraframe continue to progress farther up the roof. Today the installation of the shingles continued farther out from the center and are now to the edge of the roof. It is along the edge of the roof that we are installing wire screening to keep bugs and critters out of the space between the old sheathing, our new skip sheathing and the shingles. This second layer of skip sheathing will allow for the roof to have air flow beneath it to keep it from being damaged by moisture. The roof was then completely tarped again and made ready for tomorrow.

In thinking about the age of the building I am drawn back to the men who constructed it. There is a datestone in the northern peak of the building with the initials CD carved into it. Next to that is the word "mason." In the 1798 Federal Census there is a stone mason listed living in the area by the name of Coykendall Decker. He may be the person who built the stone structure of the building. Perhaps Martinus Decker, the Revolutionary War patriot who lived in the house completed all of the other work. From this distance we cannot know for sure.

As I watch the roofers move closer to the peak I am reminded that the original roofers were probably men. They were dressed differently of course, and one can presume that they did not install that original roof in the winter although we do not know for sure. They were probably ardent patriots, men who had either fought in the American Revolution or were witness to the many events that played out in our area. We know that Martinus Decker's motto was "Perseverance and Vigilance." What a wonderful personal motto. It harkens to the notion that we must continue to persevere this old building and be vigilant about preserving its history.

Bill Clark, Brian Lewis and me are continuing to take pictures of the work's progress.

We Proceeded On.

All photos Courtesy Peter Osborne

January 13, 2009

Weather - sunny, cold, 20 degrees

A decision was made to extend the ice shield further up the roof because of concerns about ice and water backing up under the cedar shingles and behind the inside of the stone wall. It is curious to me that the original builder already had that in mind when he built the house. There is solid planking until the top third of the roof. Our ice shield will be not go up quite as far but almost.

The drip edge and first layers of cedar shingles were installed and from there row after row cedar shingles were laid as each shingle was checked for quality and width by Duraframe employees before being installed on the roof. It is critical that the gutters between each shingle not line up with the row below otherwise it will create problems as the water drains off.

By day's end the new skip sheathing was being installed beyond the ice shield. It is thought that this half of the roof will be done by Thursday. The roof was completely tarped again and made ready for tomorrow.

As I have been watching the work being undertaken I am reminded that craftsmen like the men of Duraframe are like artists. As they check each shingle, and there will be thousands that go up on the roof, and as they nail each one to the sheathing, it is done with a skill that an artist, writer or designer has. As one who does not have those skills I admire people who do. I suppose that every once in awhile when they come down off the roof and look at their handiwork the men probably look at it like an artist does, with some wonderment, pride and a sense of accomplishment.

Bill Clark, Brian Lewis and me are continuing to take pictures of the work's progress.

We Proceeded On

All photos Courtesy Peter Osborne

January 12, 2009

Weather - sunny, very cold, 12 degrees

Today, with the thermometer hovering around fifteen degrees, and after beginning a fund-raising process that commenced almost two years ago, the Society began to replace the thirty-four year old asphalt roof on the Fort Decker Museum of History with a new historically correct cedar shingle roof. Duraframe's crew arrived on the scene first thing this morning and began work in earnest.

After the snow and ice was removed the old roof was taken off along with the sheets of homosote that were put top of the original sheathing in 1974. The shingles are in remarkably good shape since they have been on the roof for such a long time. The installation of new skip sheathing and ice shield was begun at the edge of the roof and to end the day, the roof was tarped. The flashing is much more deteriorated and will be replaced with this contract.

There were several interesting findings. The first is that the dip in the roof on the northwestern side of the building is not caused by any major structural defect. Perhaps the rafters in that part of the roof settled in the years after the construction or perhaps they were not perfectly lined up when the initial construction took place. We also confirmed that much of the skip sheathing is probably original to the building with some newer pieces replacing damaged boards as later roofs were installed.

We have begun an extensive effort to document the project for our archives at the Society and hope to enhance our knowledge of the building and its history. The includes the collecting of samples and extensively photographing the project. Bill Clark, Brian Lewis and me are all taking pictures of the work's progress.

Courtesy Peter Osborne

Courtesy Peter Osborne

Courtesy Ryan Meissner of Dura Frame

Courtesy Peter Osborne

Courtesy Peter Osborne

After a long effort we are finally underway with "Raising The Roof" on the Fort Decker Museum of History. Today the cedar shingles were delivered from Luhr's Tru-Value Hardware, scaffolding was set up and the exhibits in our museum was covered with plastic sheets. Samples of materials to be used on the project were approved and final plans were discussed with the contractor who won bid on the project, Ryan Meissner of Dura Frame. Dura Frame hails from East Stroudsburg, Pennsylvania and has completed a number of roof projects on historic buildings throughout the region including the Stable Building roof at Grey Towers National Historic Landmark.

During the course of the summer, fall and early winter we had to undertake a number of steps to get the project underway - specification approval by the state, bidding, re-bidding and then completing the paperwork necessary to implement the contracts. Finally on November 2, 2008, the roof replacement contract was approved and the final steps necessary to move forward were taken. This part of the project is being funded by the Society of Colonial Wars in The State of New Jersey, donations by members and friends of the Society, Fellenzer Engineering, Luhr's Tru-Value Hardware and the Upper Delaware Scenic Byway.

We decided to break the roof project into two distinct components, the installation of the shingle roof and the masonry work on the chimneys and the area where the roof structure meets the stone work. After a long process this contract has also been awarded to John Anderson from Cresco, Pennsylvania. After he was awarded the contract he generously agreed to do addition work along the foundation line of the building at no cost. This work is very important to maintain the structural integrity of the building. The part of the project will be funded by a grant that was secured for the Society by New York State Senator John Bonacic in the state budget last year. The contract was signed on December 24, 2008 and approvals were given to the Society by the state on December 31, 2008. The work will begin in the spring of 2009.

The Society is moving along on getting its specifications ready for the roof project. At a meeting yestereday between all the parties involved in getting the project accomplished, the final process for bidding was approved along with the format for the specifications. The specifications for the project along with the required paperwork will be sent to the New York State Historic Preservation Office in the next two weeks and will be reviewed over the next few months.

The Society is excited to announce that New York State Senator John Bonacic has been able to secure $10,000 in state funding to be used to install our new cedar shingle roof on Fort Decker. This is a major piece of the funding that was required to bring this project to fruition and our Society is very grateful to him. Senator Bonacic has long been a supporter of our Society and its projects including the Upper Delaware Scenic Byway.